It is the last few days before Christmas and the last of the preparations are being hurriedly thought about, by me, and carried out by Sue. Cakes are being cooked and the Christmas tree is making the place feel like Christmas. At this time of the year Meccano thoughts are on the Christmas Challenge that has become a regular feature in the Spanner II list. It usually causes a lot of debate and can take weeks for the rules to be clarified. It seems to be a bit of a tradition. This year, I took the bull by the horns and jumped in to proposed a Christmas Challenge much earlier than is the norm, expecting nothing more than for it to take an age to get under way.

|

| Sue's Christmas fireplace |

One of the first people to enter the competition this year was Douglas Laing from Johannesburg. Douglas had submitted a VirtualMEC drawing of a Hammer Head crane. Unfortunately I found myself in the unenviable position of having to disqualify it for not complying with the rules. Christmas challenge aside, the model was very appealing and I decided to have a go at building it. Luckily my disqualification of his entry was taken with good grace and we started corresponding regarding the build. Douglas sent me his VirtualMEC model file and it was then that the wheels started to come off of this plan. The original 'still' from the drawing is shown on the right. VirtualMEC has its limitations and one of them is that nobody taught it how part no. 40 works. For those without an encyclopaedic knowledge of meccano parts numbers, that is a Hank of Cord - String to you and me!

One of the first people to enter the competition this year was Douglas Laing from Johannesburg. Douglas had submitted a VirtualMEC drawing of a Hammer Head crane. Unfortunately I found myself in the unenviable position of having to disqualify it for not complying with the rules. Christmas challenge aside, the model was very appealing and I decided to have a go at building it. Luckily my disqualification of his entry was taken with good grace and we started corresponding regarding the build. Douglas sent me his VirtualMEC model file and it was then that the wheels started to come off of this plan. The original 'still' from the drawing is shown on the right. VirtualMEC has its limitations and one of them is that nobody taught it how part no. 40 works. For those without an encyclopaedic knowledge of meccano parts numbers, that is a Hank of Cord - String to you and me!It is very easy to draw parts in impossible positions without realising it. The trading of e-mails between London and Johannesburg began and progress was made slowly. The other thing to come out of this was the realisation that the VirtualMEC program had no 'gravity' and what would stand up in the virtual world would not necessarily do so in reality.

The Build

I started with the tower as that looked simple enough. And it is if you have all the parts. Closer inspection reveals the bracing is actually 5½ inch narrow strips. Who has twenty-four of those laying about? Even we don't have that sort of quantity to hand. These parts were not included in the sets and were only available as spare parts, which were hard to come by even when Meccano were selling spares. In fact they are so thin on the ground around here I know exactly how many we have and exactly where they all are. There are thirty-four of them built up in Sue's replica Ferris wheel dealer display model and just two more sitting in the drawer. |

| The top of the tower showing the overlapping 3 inch narrow strips joined behind the washer |

Building the outer framework was fiddly, with all those double girders, but once it was sorted out that was the easy bit. Now the fun began. Try as I might I could not get several of the narrow strips used to brace the side frames to fit anywhere near where the drawing indicated they should be. It was at this point that Douglas sent me the drawing file. Inspection of this revealed that several of the strips were indeed not aligned with the holes at all and just hidden behind the frame. In all cases the ends of the strips can be trapped between the sections of the frame. Surprisingly, this worked well and the resultant construction is perfectly rigid enough.

|

| View from above better sows the construction |

|

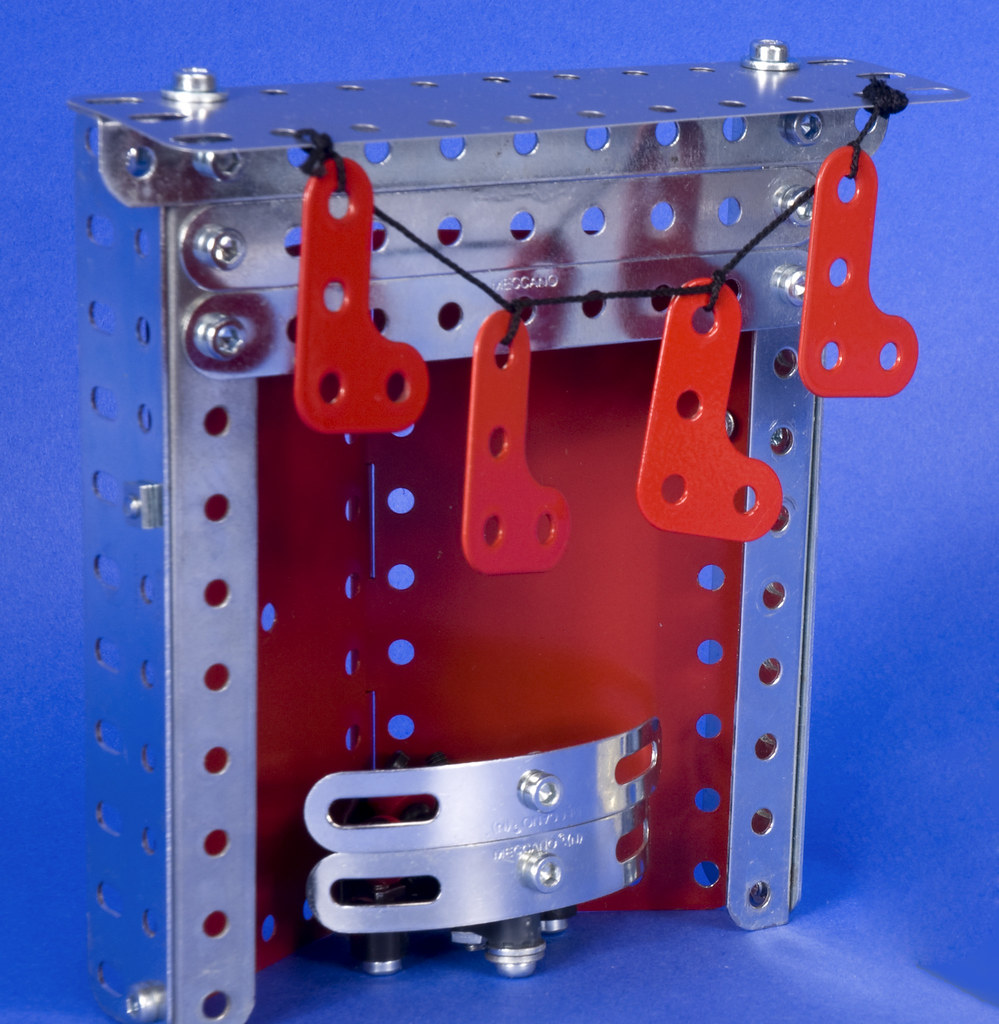

| Inside the winding house with the roof removed |

|

| The tyre is acting as a brake, held against the plate by the spring seen in the picture above |

|

| The crab incorporated a tension spring |

The hook block in the original plan uses flat trunnions in the usual configuration to make the block. However in this scale I felt it looked a little too bib so I made a slightly lighter one using a pair of brass ½ inch Pulleys without boss held between a pair of 1 inch corner brackets. A vintage red part no. 57c Hook is held between a pair of red 1 inch narrow strips. Short pivot bolts and thin brass M4 washers were used to hold the corner brackets together and space the pulleys away from the bracket to prevent them binding. Hexagonal nuts were locked together to hold everything in place, but still leaving the pulleys free to rotate. The small size of these nuts is not a great deal different from the size of the socket head bolts an therefore look better than any other solution available, such as Meccano locking nuts. A shorter 3/8 inch Long Bolt is used to suspend the hook.After assembly it was obvious that the paint in the holes of the painted parts were causing it all to bind in use. A bit on manual working in by working the pivot points by hand soon loosened it up and a few drops of oil on the pivot bolts and hook suspension gear worked wonders.

The hook block in the original plan uses flat trunnions in the usual configuration to make the block. However in this scale I felt it looked a little too bib so I made a slightly lighter one using a pair of brass ½ inch Pulleys without boss held between a pair of 1 inch corner brackets. A vintage red part no. 57c Hook is held between a pair of red 1 inch narrow strips. Short pivot bolts and thin brass M4 washers were used to hold the corner brackets together and space the pulleys away from the bracket to prevent them binding. Hexagonal nuts were locked together to hold everything in place, but still leaving the pulleys free to rotate. The small size of these nuts is not a great deal different from the size of the socket head bolts an therefore look better than any other solution available, such as Meccano locking nuts. A shorter 3/8 inch Long Bolt is used to suspend the hook.After assembly it was obvious that the paint in the holes of the painted parts were causing it all to bind in use. A bit on manual working in by working the pivot points by hand soon loosened it up and a few drops of oil on the pivot bolts and hook suspension gear worked wonders.  |

| The finished winding hose with roof |

I am please with the way it turned out and it just goes to show how Meccano manual models can models can be inspirational and lead to something completely different as the idea is passed on and evolved. Douglas said he made his drawing in an attempt to improve an old manual. Model 4.1 HAMMERHEAD CRANE from the 1951 no. 4 set.

Although Model 4.13 firm the 1962 Manual looks to be more like an ancestor of the model in his original drawing.

Either way, as he says in his original post on the Spanner II list, it can't have wheels and be called a Hammerhead crane.

Okay, that has got the crane building bug satisfied for another little while I am off to look at making an entry of my own to the Christmas Challenge over on the Spanner II list. If you are not familiar with Spanner II and want to know more, click HERE or follow the link in the light-blue Spanner II information box in the left hand column of this page.

Ralph