|

| Ekektrikit model E12 |

Like most of us, my association with Meccano goes back to my youth. Although we never went short of anything, we were not rolling in money and at times I am sure my parents sacrificed a lot to keep food on the table and pay the bills. Money for meccano was practically non-existent so I had to rely on Christmas and birthday presents to increase my stock. There was one thing that I remember always wanting, and I can remember my Father telling me he would love to be able to buy it for me but it was just not possible this year. I know he was genuine as he was obviously keen on the idea himself. The day it was possible for my Father to buy it never came. That illusive set was the Elektrikit.

Years later my father had a stroke and he and my Mother came to stay with us for a while after he had gone through a long hospitalised recovery. He was very keen to do something with his hands as a sort of therapy, so I got out the Elektrikit I had eventually acquired from the late Bert Love some years earlier. We sat in our front room, with bits all over the place, and proceeded to build some of the models we had seen in the advertising decades earlier. Although my Father's dexterity was not too good, between us we built some models. We both had a thoroughly good day and one that I will never forget.

Apart from that day I don't think I have built many (if any) models from that manual until yesterday. A post on

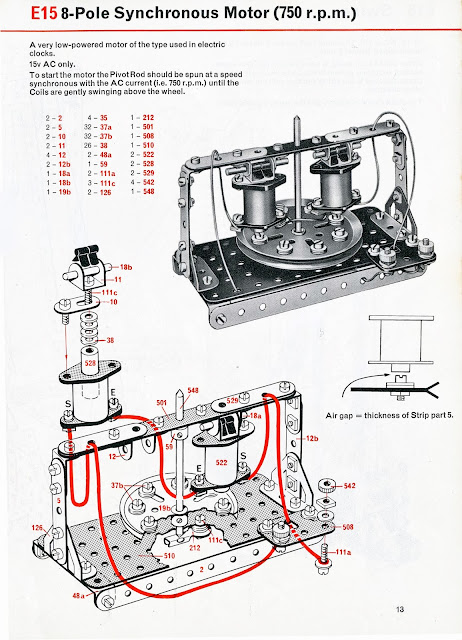

Rust Bucket, the Meccano forum, set me off again and it was out with the manual and time to select some parts. The model being discussed on the forum was model number E12, a self starting synchronous motor.

|

| The instructions for the original UK Elektrikit manual |

The model itself is straightforward. I built it to the instructions using some parts from the modern sets combined with nice clean, specially selected, Elektrikit parts. The only problem was I didn't have a 15V AC supply to hand, as the instructions recommend. and certainly not a vintage one. The nerest I have is an old Meccano 20V transformer (T20M), so that was pressed into use.

It is always worth checking the resistance of the coils to check they are not faulty. Most of mine are 16Ω (I assume this is what they were meant to be) giving a total resistance of 32Ω, as the two coils are wired in series. My T20M Transformer gives out about 24V so the current draw in round figures should be about 750 mA (V/R = I ). In fact it will probably be less as I bet there will be some resistance on all those joints!

|

| The finished model with the card removed to show the workings |

I have used genuine Elektrikit wire as I wanted to see if it worked built faithfully to the instructions. Although the build is simple, the setting up takes a bit of care. Fine adjustment to the pin-point bearings and to the ends of the strips mounted on the threaded rods really improves the running.

|

| This lower angle shot shows how close the pulley is to the strips |

The closer the pulley is to the strips the better only a minimum air gap is required. This obviously necessitates finding 3 inch pulley that runs true. I ended up using one of the dark red pulleys from the vintages set in the end. They are also a bit heaver than the blue ones.

The video shows that the finished motor that self starts and runs like a dream. Towards the end of the video, the sound cuts. This is were I have disconnected the power to the motor and it is continuing to spin, almost silently, freely in the bearings - great fun. I might just go and have a go at something else from the Elektrikit manual...

Ralph.